#Smart PLC control

Explore tagged Tumblr posts

Text

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation ��� Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

Siemens SIMATIC S7-200 SMART: The Compact PLC for Efficient Automation

The key to staying competitive in today’s soaring-tempo manufacturing space is automation. Reliable and affordable means of enhancing output and efficiency are always on the companies’ minds. To cater for small to medium-sized applications, Siemens has designed the compact but powerful SIMATIC S7-200 SMART programmable logic controller (PLC). This blog will highlight some of the SIMATIC S7-200 SMART features, advantages as well as its uses; thus, showing why it is an excellent solution for businesses trying to streamline their automation processes.

What is the SIMATIC S7-200 SMART?

The SIMATIC S7-200 SMART is a micro-PLC that delivers exceptional effectiveness in a small and tidy casing. It is a PLC of the Siemens SIMATIC family designed to efficiently deal with small automation tasks. It suits sectors where limited space is available but numerous reliable and scalable automation alternatives are sought per demand. Its user-friendly interface will assist so much while handling different industrial projects like controlling machines, building automation as well as regulating processes.

Key Features of SIMATIC S7-200 SMART

Compact Design: S7-200 SMART is designed considering space constraints. It’s perfectly sized to fit in tight spots, making it a great solution for systems requiring utmost compactness.

High Performance: The processing power of S7-200 SMART is great even though it’s small. With rapid execution speeds that are adhered to, automation processes can be controlled quickly and precisely.

Flexible Communication: The S7-200 SMART contains a lot of various sets of standards regarding communication such as RS485, Ethernet and Modbus RTU thus it can easily be linked with any other system already existent at that moment using less complexity and making communication simple for all other gadgets.

Scalability: With its modular construction, the S7-200 SMART is simple to expand. Should your needs change or grow, you have the option of adding new modules which can guarantee that the PLC keeps pace with your company’s growth and shifting needs.

User-Friendly Programming: Programming the S7-200 SMART is significant as it is simple without the quagmire of STEP 7-Micro/WIN SMART software. It is an intuitive programming environment that makes quick development, debugging, and deploying of automation solutions possible through engineers and technicians always being at their fingertips on the keyboard.

Cost-Effective Solution: At an inexpensive cost, the S7-200 SMART has been made to render maximum benefits. It has got all the necessary attributes that are vital in small automation works with no decline in quality or efficacy.

Applications of SIMATIC S7-200 SMART

The SIMATIC S7-200 SMART is versatile and thus can be used in various applications in different industries:

Machine Automation: S7-200 SMART is the best suited for controlling small to medium size machines (packaging machines, conveyor systems, etc). This means that it has high processing speeds that help ensure smooth and efficient operation of machinery.

Building Automation: The S7-200 SMART is a programmable logic controller which can monitor and control illumination, HVAC systems and safety systems in building automation. It is small in size; hence its scalability enables it to serve as an excellent option for integrating multiple building systems into one control platform.

Process Control: The S7-200 SMART is highly suitable for applications in process control in industries such as water treatment, food and beverage, and chemical processing. Its capability to execute complex control tasks with great precision ensures continuity and dependability in processing results.

Energy Management: Energy management systems are equipped with S7-200 SMART that can help to monitor and control energy consumption. This will aid the companies in achieving their goals of reducing energy use, cutting costs as well as enhancing general purposes for power efficiency.

Why Choose SIMATIC S7-200 SMART?

Once again, it is a case of the SIMATIC S7-200 SMART being the best option for a PLC that is reliable, affordable and the best option to choose for automation in your enterprise. There are some reasons why you should think about buying this one:

Proven Siemens Quality: A global forerunner in industrial automation, Siemens has a high-quality and reliable S7-200 SMART.

Ease of Use: Deploying the S7-200 SMART is simple owing to the available programming package that is quite straightforward and an interface that is very uncomplicated, hence less time and effort are used in executing it.

Adaptability: The S7-200 SMART features a modular and growing design tailored to fit your shiftable requirements in company thus a forever investment.

Global Support: Siemens provides extensive technical assistance and resources that can allow you make maximum use of your S7-200 SMART irrespective of your location on earth.

Conclusion

Small to medium-sized automation applications are easy to realize with the help of a powerful and compact PLC known as the Siemens SIMATIC S7-200 SMART. Those who want to improve their processes without investing huge amounts of money should consider it because of its high performance, flexibility and user-friendliness.

Whether you want to mechanize machines, control the systems in a building, or oversee complicated processes, S7-200 SMART has the attributes as well as dependability required for success. As an approved distributor for various Siemens automation items, Naksh Technology has a duty to provide comprehensive solutions for industrial automations which include SIMATIC S7-200 SMART in its lineup.

0 notes

Text

How Switchgears Contribute to Power Quality and Equipment Longevity

In today’s industrial landscape, facility uptime, energy efficiency, and equipment lifespan are directly tied to power quality. Poor power quality doesn’t just inflate energy costs — it silently wears down critical machinery, causes unexpected shutdowns, and leads to costly repairs. One often overlooked hero in this equation is the switchgear. Modern switchgears do far more than just control and protect power circuits; they actively safeguard power quality and extend the life of your equipment.

In this article, we’ll explore the vital role switchgears play in maintaining power quality and ensuring long-term reliability in industrial and commercial facilities.

Understanding Power Quality: Why It Matters

Power quality refers to the stability, reliability, and cleanliness of the electrical power supplied to equipment. Factors that degrade power quality include:

· Voltage sags and swells

· Harmonic distortion

· Transient surges

· Frequency variations

· Imbalance between phases

When power quality is compromised, sensitive equipment like drives, motors, PLCs, and even lighting systems can suffer reduced lifespan, malfunction, or complete failure. High-quality power is not a luxury; it’s a necessity for operational efficiency and safety.

Switchgears: The Gatekeepers of Power Integrity

Switchgears serve as the nerve center of power distribution in any facility. Here’s how modern switchgear solutions help maintain and enhance power quality:

1. Voltage Regulation and Stabilization

Advanced switchgears monitor voltage levels in real time and protect equipment from harmful sags or swells. Features like automatic voltage regulation and voltage balancing ensure your sensitive loads receive stable power, preventing stress on motors and electronic devices.

2. Harmonic Filtering

Some modern switchgear systems come integrated with harmonic filters or support external filtering solutions. Harmonics generated by variable frequency drives (VFDs), UPS systems, and other non-linear loads can cause overheating and inefficiencies. Switchgears mitigate these distortions, protecting downstream equipment and improving overall energy efficiency.

3. Surge and Transient Protection

Switchgears equipped with surge protection devices (SPDs) act as the first line of defense against voltage spikes and transient surges caused by lightning strikes or grid switching events. This protection extends the life of connected equipment by shielding them from these destructive forces.

4. Fault Isolation and Selectivity

When a fault occurs, fast-acting circuit breakers within the switchgear isolate the problem area without disrupting power to the entire facility. This selectivity ensures that critical processes continue running while the fault is contained, preventing system-wide stress and downtime.

5. Power Factor Correction (PFC)

Switchgears can be integrated with power factor correction capacitors that optimize the power factor, reducing losses and improving voltage stability. A better power factor not only saves on utility bills but also reduces the strain on transformers and generators, thus enhancing their longevity.

Equipment Longevity: The Silent Benefit of Quality Power

The connection between switchgears and equipment lifespan is profound:

· Motors last longer when protected from voltage imbalances and harmonics.

· Transformers operate cooler and more efficiently when power factor is optimized.

· Variable Speed Drives (VSDs) avoid overheating when shielded from surges and harmonic distortions.

· Sensitive electronic controls avoid malfunction due to transient spikes and voltage dips.

In essence, well-maintained and properly specified switchgear reduces the electrical “stress” that causes premature equipment aging and failure.

The Shift Toward Digital and Smart Switchgears

The rise of digital switchgear takes power quality management to the next level. Smart switchgears offer:

· Continuous real-time monitoring of voltage, current, harmonics, and power factor

· Predictive analytics to forecast equipment wear and prevent failures

· Remote control and automated fault response for faster issue resolution

Facilities that embrace digital switchgear solutions can transform their maintenance strategies from reactive to proactive, leading to even longer equipment lifespans and lower total ownership costs.

Practical Steps: How to Maximize the Benefits

To harness the full power quality and longevity benefits from switchgears, consider the following best practices:

· Regular Maintenance: Inspect and test switchgear components to ensure optimal performance.

· Correct Specification: Choose switchgears rated for your facility’s load characteristics and future growth.

· Integration with Monitoring Systems: Leverage real-time data to track power quality indicators.

· Invest in Smart Solutions: Upgrade to digital switchgears with built-in diagnostics and analytics.

Conclusion: Switchgears as Strategic Assets

Switchgears are far more than circuit controllers; they are strategic assets that can directly impact your facility’s operational excellence. By stabilizing power quality, filtering disturbances, and protecting against electrical faults, switchgears extend the service life of every connected piece of equipment — from heavy-duty motors to delicate electronic controls.

For engineers, procurement managers, and facility operators, investing in high-quality, modern switchgear solutions isn’t just about compliance — it’s about securing long-term savings, boosting reliability, and optimizing performance.

#low voltage#switchgear#electrical#electrical supplies#911 abc#artists on tumblr#cats of tumblr#cookie run kingdom#batman#arcane#f1#jason todd#electricity#electric vehicles#ides of march

6 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

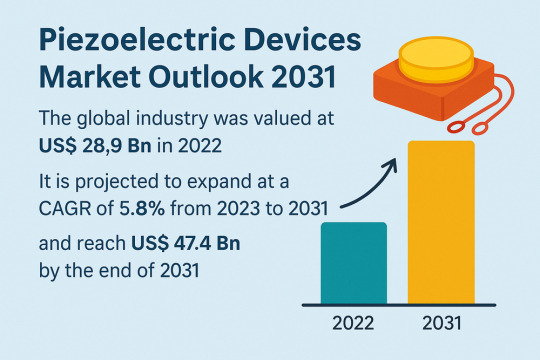

Versatile Applications Power Global Piezoelectric Devices Market to USD 47.4 Bn by 2031

The global piezoelectric devices market was valued at USD 28.9 Bn in 2022 and is anticipated to reach USD 47.4 Bn by 2031, expanding at a CAGR of 5.8% during the forecast period (2023–2031). Piezoelectric devices, which convert mechanical stress into electrical signals and vice versa, are becoming indispensable across a wide array of industries including consumer electronics, automotive, industrial automation, and healthcare. Their ability to deliver high sensitivity, quick response, and energy efficiency has made them critical components in modern technological systems.

Market Drivers & Trends One of the primary growth drivers is the increasing consumption of piezoelectric devices in consumer electronics, such as smartphones, wearables, and touchscreen interfaces. Additionally, automotive advancements, especially in electric and autonomous vehicles, are fueling demand for precision sensors and actuators based on piezoelectric technology.

Another key trend is the integration of piezoelectric materials in energy harvesting applications, enabling the capture of ambient vibrations or movements to power small devices. Moreover, the miniaturization of electronic components and the growing demand for compact, energy-efficient solutions across sectors continue to support market expansion.

Key Players and Industry Leaders The global market is moderately fragmented, with key players focusing on technological innovation and strategic collaborations. Prominent companies include:

APC International Ltd.

Cedrat Technologies S.A

CeramTec GmbH

Ionix Advanced Technologies

KEMET Corporation

KYOCERA Corporation

L3harris Technologies, Inc.

Morgan Advanced Materials plc

Nanomotion Ltd.

Physik Instrumente (PI) GmbH & Co. KG

Piezo Kinetics, Inc.

piezosystem jena GmbH

These companies are investing heavily in R&D to develop next-generation piezoelectric materials and solutions.

Discover essential conclusions and data from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=34574

Recent Developments

KAIST, April 2023: Developed wearable piezoelectric sensor for continuous blood pressure monitoring.

SFedU, March 2023: Created piezoelectric generators from carbon nanotubes for urban noise-to-energy applications.

Piezo Motion Corp., March 2021: Acquired Discovery Technology International to diversify into precision piezoelectric motors.

Latest Market Trends

Wearable Sensors for Health Monitoring: In April 2023, KAIST developed a highly sensitive wearable piezoelectric blood pressure sensor, paving the way for real-time health monitoring applications.

Energy Harvesting Innovations: Russian researchers at SFedU have developed piezoelectric generators based on nitrogen-alloyed carbon nanotubes to transform urban vibrations into usable power.

Affordable Precision Motors: In March 2021, Piezo Motion Corp. acquired Discovery Technology International, expanding its offering of affordable, energy-efficient piezoelectric motors.

Market Opportunities The piezoelectric devices market offers numerous growth opportunities:

Expansion in healthcare monitoring devices and smart wearable sensors.

Increased deployment in automotive sensors for braking, collision detection, and autonomous navigation.

Adoption in industrial automation for process monitoring and control.

New applications in IoT and smart home devices, from vibration sensors in washing machines to alert systems in refrigerators.

As the demand for real-time data, energy efficiency, and miniaturization continues, piezoelectric devices are poised to benefit substantially.

Future Outlook The market is set to witness sustainable and diversified growth driven by continuous advancements in material sciences, nanotechnology, and integration capabilities. Emerging economies, particularly in Asia Pacific, are likely to lead due to expanding manufacturing bases, government incentives, and growing demand for smart consumer devices and electric vehicles.

Market Segmentation The market is segmented as follows:

By Type

Piezoelectric Sensors

Piezoelectric Actuators (Stack, Strip, Shear, Tube)

Piezoelectric Motors

Piezoelectric Generators

Piezoelectric Transducers

Others (Transformers, Resonators)

By Material

Piezoelectric Crystals

Piezoelectric Ceramics

Piezoelectric Polymers

Piezoelectric Composites

By Element

Discs

Rings

Plates

By Application

Sonar

Acceleration Sensors

Smartphones

Machining Tools

Others (NDT, surgical tools)

By End-use Industry

Aerospace & Defense

Automotive

Consumer Electronics

Industrial & Manufacturing

Others (Healthcare, Oil & Gas)

Regional Insights

Asia Pacific dominated the market in 2022 with 42.1% share, owing to high demand for electric vehicles, smartphones, and the presence of several manufacturers in China, Japan, South Korea, and India.

North America held 28.05% share, led by technological innovations, strong R&D investments, and the presence of major players such as APC International and Morgan Advanced Materials.

Europe continues to be a steady contributor, especially in the automotive and industrial automation sectors.

Latin America, Middle East & Africa are emerging markets, expected to witness moderate growth due to improving infrastructure and industrialization.

Why Buy This Report?

In-depth market forecast and analysis from 2023 to 2031.

Comprehensive segmentation and regional outlook for informed decision-making.

Competitive landscape assessment, including company profiles, strategies, and recent developments.

Insights into technological advancements and emerging applications.

Support for strategic investment planning and new product development.

Frequently Asked Questions

1. What is the current size of the global piezoelectric devices market? The market was valued at US$ 28.9 Bn in 2022.

2. What is the projected market size by 2031? The market is expected to reach US$ 47.4 Bn by 2031, growing at a CAGR of 5.8%.

3. Which region dominates the global market? Asia Pacific leads the market, accounting for over 42% share in 2022.

4. What are the major applications of piezoelectric devices? Key applications include smartphones, automotive sensors, healthcare monitoring devices, sonar systems, and machining tools.

5. Who are the key players in the market? Leading companies include KYOCERA Corporation, KEMET Corporation, APC International Ltd., CeramTec GmbH, Morgan Advanced Materials plc, among others.

6. What are the future growth opportunities? Major opportunities lie in wearable health tech, energy harvesting, autonomous vehicles, and smart home devices.

Explore Latest Research Reports by Transparency Market Research: GaN Epitaxial Wafers Market: https://www.transparencymarketresearch.com/gan-epitaxial-wafers-market.html

Silicon Carbide MOSFETs Market: https://www.transparencymarketresearch.com/silicon-carbide-mosfets-market.html

GaAs Photodiode Market: https://www.transparencymarketresearch.com/gaas-photodiodes-market.html

Semiconductor Plating System Market: https://www.transparencymarketresearch.com/semiconductor-plating-system-market.html About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

High-Performance Lollipop Machine Solutions by Latini-Hohberger Dhimantec

Latini-Hohberger Dhimantec stands at the forefront of the confectionery machinery industry, delivering exceptional and innovative equipment that powers modern candy production worldwide. Among their leading solutions, the Lollipop Machine, Lollipop Packing Machine, and Lollipop Wrapping Machine have become indispensable tools for manufacturers aiming for precision, hygiene, and speed in the production line. Designed with cutting-edge technology and decades of engineering expertise, these machines offer complete automation in shaping, cooling, packaging, and wrapping of lollipops—ensuring consistent quality and high output with minimal human intervention.

The Lollipop Machine by Latini-Hohberger Dhimantec is engineered for excellence, catering to a wide variety of lollipop shapes and sizes. Whether it's flat, round, oval, or 3D forms, the machine accommodates different molds and configurations, making it a versatile solution for candy producers. Equipped with high-speed forming capabilities, the Lollipop Machine guarantees precision molding, controlled weight distribution, and seamless integration with downstream packing and wrapping systems. The robust stainless steel build and easy-to-clean surfaces ensure hygienic processing, while the smart control systems make operation simple and efficient for operators of all skill levels.

A standout feature of Latini-Hohberger Dhimantec’s machinery is its seamless transition from formation to packaging. The Lollipop Packing Machine complements the production line by automating the bagging, flow wrapping, or stick insertion processes depending on the chosen packaging style. This machine operates at high speeds without compromising on the quality of seal integrity or visual presentation. Perfect for both small-scale boutique operations and large-scale mass production, the Lollipop Packing Machine ensures that every product is handled delicately yet quickly, maintaining product integrity from start to finish. Advanced sensors and PLC-based control systems allow for real-time monitoring and adjustments, reducing downtime and optimizing productivity.

When it comes to aesthetic appeal and hygienic sealing, the Lollipop Wrapping Machine is the ultimate solution. Available in both single twist and bunch wrap configurations, it provides reliable, high-speed wrapping that not only preserves freshness but also enhances visual appeal—making it ideal for both retail and export markets. Designed for ease of operation, minimal maintenance, and maximum uptime, the Lollipop Wrapping Machine incorporates servo-driven systems that ensure each wrap is tight, centered, and tamper-evident. The compact layout of this machine also makes it space-efficient, and its modular design allows manufacturers to upgrade or integrate with existing systems easily.

These three machines—Lollipop Machine, Lollipop Packing Machine, and Lollipop Wrapping Machine—form a complete production-to-packaging ecosystem. Manufacturers no longer need to rely on multiple vendors or worry about inter-system compatibility. Latini-Hohberger Dhimantec’s integrated solutions are built to function in harmony, reducing errors, increasing production rates, and ensuring that every lollipop meets the brand’s standards of quality, hygiene, and presentation.

Another hallmark of Latini-Hohberger Dhimantec’s machinery is its focus on safety and compliance. All equipment adheres to international food safety standards, including FDA and CE certifications. The company also prioritizes energy efficiency, reducing environmental impact while keeping operating costs low. With safety shields, emergency stop buttons, and real-time alert systems, the machines not only protect the product but also ensure the well-being of machine operators.

Maintenance and servicing are made easy with user-friendly interfaces and remote diagnostics. Latini-Hohberger Dhimantec provides extensive support post-installation, including training, spare parts availability, and 24/7 technical assistance. Their global network ensures fast service response times, which helps manufacturers maintain continuous production cycles with minimal interruptions. Additionally, clients can request customization features or retrofitting solutions to adapt older machinery to newer, more energy-efficient formats.

The global confectionery market is highly competitive, and product differentiation starts with quality and consistency. Latini-Hohberger Dhimantec understands these challenges and builds its machinery to empower candy manufacturers with the tools they need to lead the market. Whether a company is looking to scale up operations or introduce a new line of products, the Lollipop Machine, Lollipop Packing Machine, and Lollipop Wrapping Machine provide the reliability, performance, and flexibility needed to stay ahead in the industry.

Moreover, the machines are designed with scalability in mind. As production demands increase, manufacturers can add new modules or synchronize with other processing units without having to overhaul their entire setup. The modular approach also supports innovation in candy design, enabling producers to experiment with new shapes, flavors, and packaging styles. From product development to final packaging, Latini-Hohberger Dhimantec machinery allows for experimentation without sacrificing efficiency.

In today’s consumer-driven environment, appearance, packaging, and shelf life are as crucial as taste. The high-quality output from the Lollipop Machine ensures uniform shapes and smooth textures. The Lollipop Packing Machine protects the product from moisture and external contaminants, while the Lollipop Wrapping Machine adds the final visual flourish that attracts buyers at point-of-sale. Together, they create a production pipeline that supports branding, logistics, and customer satisfaction.

Clients across the globe—from North America to Southeast Asia—trust Latini-Hohberger Dhimantec for their reliability, innovation, and engineering precision. Their commitment to technological advancement, customer service, and long-term value makes them the preferred partner for confectionery businesses aiming for excellence in manufacturing and presentation.

To conclude, Latini-Hohberger Dhimantec offers a comprehensive suite of confectionery solutions that address the complete lifecycle of lollipop production. Their Lollipop Machine, Lollipop Packing Machine, and Lollipop Wrapping Machine are more than just tools—they are strategic investments that enhance quality, boost production, reduce waste, and future-proof confectionery businesses for years to come. By choosing these advanced machines, manufacturers align themselves with a legacy of engineering brilliance and a vision for sustainable, high-quality candy production.

0 notes

Text

The Role of SINAMICS V20 in Smart Food Manufacturing

As Industry 4.0 evolves, food production is changing with new technologies. Companies are focusing on automation, efficiency, and sustainability. One of the main technology helping with this change is the SINAMICS V20, a Siemens drive that plays a big role in smart food manufacturing.

This blog explores the discussion on how the SINAMICS V20, a Siemens drive, is shaping food processing, packaging, and logistics, with Naksh Technology spearheading the implementation of these solutions.

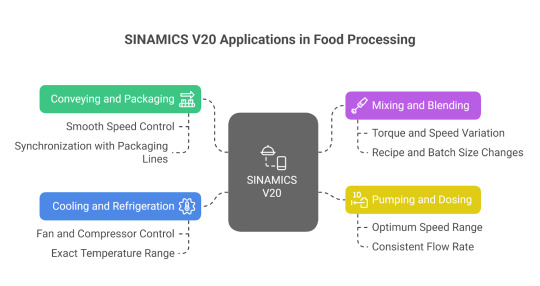

SINAMICS V20: The Backbone of Basic Automation

The SINAMICS V20 is a small, cost-effective AC drive for the basic motion control application. Owing to its versatility and simplicity, it perfectly suits the food industry whose requirements vary from conveyor systems to mixers and pumps. With power ratings from 0.12 kW up to 30 kW, it helps execute tasks in the food processing line that demand smooth and energy-efficient operation.

Also learn more about How SINAMICS V20 Boosts Operational Flexibility In A Food Processing Plant.

Why Smart Food Manufacturing Needs Advanced Drives

Modern food manufacturing is all about precision and flexibility, apart from soaring speed. With consumer preference changes and ever-tightening regulations, manufacturers find themselves in a fast lane to quickly adapt to new recipes, packaging formats, and safety standards. Industrial automation powered by variable frequency drives (VFDs) such as the Siemens VFD V20 becomes essential.

Key Features of SINAMICS V20 in Food Manufacturing

Easy Installation and Commissioning: The SINAMICS V20 can be mounted either with push-through mounting or wall mounting, allowing for fast installation and side-by-side configuration to save on-floor space on crowded factory floors.

Energy Efficiency: It helps food manufacturers reduce their energy consumption by about 60%, a vital parameter for sustainable production, through automatic flux reduction and the ECO and hibernation modes.

Robustness and Reliability: With a unique cooling design, conformal-coated PCBs, and a vast voltage range, the drive is engineered to work within the rough environment of a food factory to minimize downtime and maintenance expenses.

Flexible Control Modes: The drive facilitates process enhancements through various control modes such as V/f, V2/f, FCC, and multi-point, according to differing machine requirements.

The Siemens Drive Advantage in Food Processing

Siemens drives are known for their integration and compatibility with automation systems. Siemens Sinamics family, including SINAMICS V20, is easily connected through PLCs, sensors, and cloud monitoring platforms. Such connectivity is important for smart food manufacturing, whereby it allows real-time process monitoring, predictive maintenance, and making decisions based on data.

Applications of SINAMICS V20 in Food Manufacturing

1. Conveying and Packaging

The movement of raw materials and finished goods must be smooth in food plants. SINAMICS V20 drives conveyors through smooth speed control to ensure the delicate products are gently handled and synchronized with packaging lines to reduce wastage and maximize throughput.

2. Mixing and Blending

Mixers and blenders require speed regulation with precision for the sake of consistent product quality. SINAMICS V20, therefore, supplies required torque and speed variation that is reactive to sudden recipe and batch size changes.

3. Pumping and Dosing

Dosing ingredients and fluids accurately forms the foundation of food production. The SINAMICS V20 ensures that the pumps are operating at speeds in the optimum range, thus saving energy and delivering a consistent flow rate for quality assurance.

4. Cooling and Refrigeration

Temperature maintenance is essential for food safety. The SINAMICS V20 controls the fans and compressors in a refrigeration system, ensuring minimum power consumption while maintaining an exact temperature range.

Naksh Technology: Your Partner in Smart Automation

Naksh Technology is leading provider of Siemens drive solutions with an area of expertise in the integration and support of SINAMICS V20 with food manufacturing plants. With the best knowledge in industrial automation, Naksh Technology guarantees trouble-free implementation together with design, up to after-sales service, enabling the food producers to realize the full power of Siemens VFD V20 and indeed of the entire Siemens Sinamics offering.

Benefits of SINAMICS V20 for Food Manufacturers

Cost Savings: The engineering, commissioning, and operational expenses are very low considering the drive's simplicity and efficiency.

Sustainability: Integrated energy-saving mechanisms support green manufacturing initiatives and set the path for global sustainability programs.

Scalability: SINAMICS V20 can be simply scaled onto any other production line whether small or big.

Future-Ready: With the digital connectivities, the drive is ready to integrate into the Industry 4.0 scenario for cloud-based analytics and remote monitoring.

Why Choose Siemens VFD V20 from Naksh Technology?

Naksh Technology, with its vast expertise in deploying SINAMICS V20, provides food manufacturers:

Tailored automation solutions for specific food industry challenges.

Reliable technical support and training for maintenance staff.

Access to the latest Siemens Sinamics innovations for continuous improvement.

Conclusion

The SINAMICS V20 acts as a green, smart, and efficient food manufacturer. As changes take place in the food industry, Naksh Technology and the Siemens drive solutions such as the Siemens VFD V20 stand for your operations, to keep them competitive, flexible, and future-ready. Go industrial in automation with Siemens Sinamics and change your food manufacturing journey. Contact us for more information!

0 notes

Text

Aircraft Sensors Market Size, Share, Demand, Growth and Global Industry Analysis 2034

Aircraft Sensors Market is playing a pivotal role in the advancement of aviation technology, with the market projected to grow from $4.2 billion in 2024 to $8.5 billion by 2034, at a CAGR of approximately 7.3%. Aircraft sensors are integral to ensuring flight safety, monitoring performance, and improving overall operational efficiency. These sensors include pressure, temperature, proximity, and speed sensors, among others, which work seamlessly within an aircraft’s systems to provide real-time data for navigation, communication, fuel management, and engine monitoring. As aviation embraces digitalization and automation, the demand for advanced, reliable sensor technologies continues to rise across both commercial and military sectors.

Market Dynamics

The aircraft sensors market is experiencing substantial growth fueled by the aerospace industry’s shift toward smarter, safer, and more efficient aircraft. Leading this charge are sensors integrated into avionics systems, which have become increasingly sophisticated to support fly-by-wire systems, real-time diagnostics, and autonomous flight capabilities. Pressure and temperature sensors are the most widely used, holding significant market shares due to their critical role in engine health monitoring and environmental control.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS25456

Another strong growth driver is the increasing global air traffic, which necessitates not only new aircraft but also modernization of existing fleets. As airlines seek to enhance fuel efficiency and reduce emissions, sensors that enable precise engine monitoring and predictive maintenance are in high demand. On the flip side, the market faces challenges such as high development and certification costs, complex integration processes, and disruptions in the global semiconductor supply chain. These challenges, however, are met with innovations in smart sensor technologies, driven by the adoption of the Internet of Things (IoT) and artificial intelligence (AI) in aviation systems.

Key Players Analysis

The aircraft sensors market is highly competitive, with established players leading innovation and setting industry standards. Honeywell Aerospace, TE Connectivity, and Rockwell Collins are dominant forces, leveraging decades of aerospace experience to offer a diverse portfolio of sensors. These companies continually invest in R&D to improve sensor reliability, reduce weight, and enhance data processing capabilities.

Other key players like Safran Electronics & Defense, Thales Group, Curtiss-Wright, and Meggitt PLC contribute significantly to the market with advanced sensor solutions tailored to specific aircraft systems. Meanwhile, emerging players such as Aero Sense Innovations, Avionics Insight, and Sky Tech Dynamics are bringing disruptive technologies to the table, focusing on miniaturized, wireless, and multifunctional sensors. Strategic collaborations, mergers, and acquisitions are increasingly common as companies seek to enhance their product offerings and expand their global footprint.

Regional Analysis

North America remains the frontrunner in the aircraft sensors market, thanks to the presence of leading aerospace manufacturers, robust R&D infrastructure, and defense spending. The U.S. leads this regional growth, driven by innovation in avionics and strong support from regulatory agencies like the FAA.

Europe follows closely, with countries such as Germany, France, and the UK investing heavily in sustainable aviation technologies. The region’s focus on compliance with environmental and safety standards is a strong catalyst for sensor market expansion.

Asia-Pacific is emerging rapidly, propelled by booming air travel, increasing aircraft production, and the modernization of aviation infrastructure in countries like China and India. These nations are significantly expanding their aerospace capabilities, with government support further accelerating sensor adoption.

The Middle East and Africa present promising opportunities, especially in the Gulf states, where fleet modernization and airport development projects are underway. Latin America also shows steady growth, particularly in Brazil and Mexico, where aerospace industries are growing and placing greater emphasis on air safety and efficiency.

Recent News & Developments

The aircraft sensors market is seeing notable technological shifts. Companies are moving toward smart sensors that not only collect data but also analyze it in real time, enhancing operational responsiveness and decision-making. The integration of IoT and wireless communication into sensor design is revolutionizing aircraft systems by enabling remote diagnostics and continuous performance monitoring.

Recent regulatory changes by FAA and EASA have introduced stricter guidelines for sensor performance, prompting companies to refine testing and certification processes. Additionally, the global focus on fuel efficiency and carbon reduction has led to the development of sensors that contribute to optimizing flight routes and engine operation.

Noteworthy industry moves include Honeywell’s expansion into AI-powered sensor platforms and Thales’ investment in next-gen sensor integration for autonomous flight technologies. Meanwhile, supply chain vulnerabilities — especially due to semiconductor shortages — continue to affect production cycles and cost structures across the market.

Browse Full Report : https://www.globalinsightservices.com/reports/aircraft-sensors-market/

Scope of the Report

This report offers a comprehensive analysis of the Aircraft Sensors Market from 2025 to 2034. It covers critical aspects such as sensor types (pressure, temperature, proximity, etc.), products (wired, wireless, smart), technologies (MEMS, optical, infrared), and applications including engine monitoring, fuel management, and flight control. The analysis spans across commercial, military, and UAV segments, capturing trends in onboard, embedded, and remote sensor installations.

Additionally, the report dives into market drivers, trends, restraints, and opportunities. It explores regulatory impacts, innovation trends, and the role of sustainability in shaping future sensor technologies. By identifying competitive strategies and evaluating emerging players, the report provides a strategic roadmap for stakeholders aiming to navigate this high-tech, fast-evolving market landscape.

Discover Additional Market Insights from Global Insight Services:

Air Filters Market : https://www.globalinsightservices.com/reports/air-filters-market/

Deployable Military Shelter Market : https://www.globalinsightservices.com/reports/deployable-military-shelter-market/

Gaskets and Seals Market : https://www.globalinsightservices.com/reports/gaskets-and-seals-market/

Inflight Catering Market : https://www.globalinsightservices.com/reports/inflight-catering-market/

Combat Management System Market ; https://www.globalinsightservices.com/reports/combat-management-system-market/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Logic Buffer Market: Size, Share, and Trends 2025–2032

MARKET INSIGHTS

The global Logic Buffer Market size was valued at US$ 2,670 million in 2024 and is projected to reach US$ 4,780 million by 2032, at a CAGR of 8.73% during the forecast period 2025-2032.

Logic buffers are essential components in digital electronics that provide signal isolation and amplification between circuits. These devices maintain signal integrity by preventing loading effects, enabling clean signal transmission across different sections of electronic systems. Key product types include single-ended buffers and tri-state buffers, with the former segment projected to reach USD 850 million by 2032.

Market growth is driven by increasing demand from consumer electronics and automotive sectors, where logic buffers ensure reliable operation of complex circuit boards. The rising adoption of 5G technology and IoT devices further accelerates demand. Key players like Texas Instruments, NXP Semiconductors, and STMicroelectronics dominate the market, collectively holding over 45% revenue share in 2024 through advanced buffer solutions.

MARKET DYNAMICS

MARKET DRIVERS

Rapid Expansion of Consumer Electronics to Accelerate Logic Buffer Demand

The surge in global consumer electronics production is significantly boosting the logic buffer market. With smart devices becoming indispensable in daily life, manufacturers are integrating advanced semiconductor components to enhance performance. Consumer electronics shipments are projected to exceed 3 billion units annually by 2030, creating massive demand for signal conditioning components like logic buffers. These devices ensure signal integrity across increasingly complex circuit designs found in smartphones, tablets, and wearables. Recent innovations in 5G-enabled devices further amplify this need, as higher frequency operations require more robust signal buffering solutions.

Automotive Electronics Revolution to Fuel Market Growth

The automotive industry’s transformation toward electrification and autonomous driving is generating unprecedented demand for logic buffers. Modern vehicles now incorporate over 3,000 semiconductor components, with advanced driver-assistance systems (ADAS) accounting for nearly 30% of semiconductor content. Logic buffers play a critical role in managing sensor data processing and ECU communications in these systems. The automotive semiconductor market is growing at approximately 12% CAGR, directly benefiting buffer IC manufacturers. Furthermore, the transition to 48V architectures in electric vehicles presents new opportunities for high-voltage buffer solutions.

Industrial Automation Boom Drives Buffer Adoption

Industrial automation is undergoing rapid digital transformation, with the global smart factory market expected to surpass $1 trillion by 2030. Logic buffers are essential in industrial control systems, particularly in PLCs and motor drives where signal integrity is paramount. The growing adoption of Industry 4.0 technologies has increased deployment of high-speed data acquisition systems that rely on buffer ICs for noise immunity. Additionally, the rise of edge computing in manufacturing necessitates robust signal conditioning components at the network periphery, particularly in harsh industrial environments where electromagnetic interference is prevalent.

MARKET RESTRAINTS

Component Miniaturization Challenges Limit Design Flexibility

The relentless push for smaller form factors in electronics presents significant challenges for buffer IC implementation. As package sizes shrink below 01005 dimensions (0.4mm x 0.2mm), maintaining signal integrity while reducing footprint becomes increasingly difficult. Many buffer circuits require specific layout considerations that conflict with space constraints in modern designs. This technical hurdle is particularly acute in mobile applications where PCB real estate is severely limited. Furthermore, miniaturization often necessitates trade-offs in power handling capability, forcing designers to choose between size and performance.

Supply Chain Disruptions Impact Semiconductor Availability

The semiconductor industry continues to face supply-demand imbalances that affect logic buffer production. Lead times for certain buffer ICs have extended to 40+ weeks in recent years, disrupting product development cycles. While capacity expansions are underway, the capital-intensive nature of semiconductor manufacturing means shortages may persist in specialized segments. Automotive-grade buffer ICs face particular challenges as qualification processes limit alternative sourcing options. These supply constraints not only delay projects but also drive up component costs, particularly for low-volume specialty applications.

Design Complexity Increases Time-to-Market

Modern electronic systems require buffers with increasingly sophisticated features such as programmable drive strength and adaptive termination. Implementing these advanced functions while maintaining signal integrity adds significant design complexity. Many engineering teams lack the specialized expertise required to optimize buffer configurations for high-speed applications, leading to prolonged development cycles. The proliferation of different logic standards (LVCMOS, LVDS, HCSL) further complicates buffer selection and implementation, particularly in mixed-signal environments.

MARKET CHALLENGES

Thermal Management Constraints in High-Density Designs

As electronics packing densities increase, thermal management becomes a critical challenge for buffer IC implementations. Modern systems generate substantial Joule heating from simultaneous switching of numerous buffer outputs. Without proper thermal design, sustained operation at elevated temperatures can degrade signal integrity and reduce component lifespan. This issue is particularly acute in automotive and industrial applications where ambient temperatures may exceed 85°C. Designers must carefully analyze thermal resistance parameters and often incorporate additional cooling solutions, adding cost and complexity.

Other Challenges

Signal Integrity at Higher Frequencies The transition to faster data rates in serial communications requires buffers to maintain signal integrity above 10Gbps. At these frequencies, parasitic effects and transmission line characteristics dominate buffer performance. Achieving consistent edge rates while minimizing jitter becomes increasingly difficult, often requiring specialized IC processes and advanced packaging techniques. These technical demands significantly increase development costs for high-performance buffer solutions.

Power Consumption Optimization Low-power design requirements conflict with the need for robust signal driving capability in many applications. Designers must carefully balance buffer drive strength against power budgets, particularly in battery-operated devices. Advanced process nodes help reduce static power consumption, but dynamic power remains a challenge in high-speed applications where buffers toggle frequently. This power-performance trade-off is a persistent challenge across consumer, automotive, and industrial segments.

MARKET OPPORTUNITIES

Emerging AI Hardware Creates New Buffer Applications

The rapid development of AI accelerators and neuromorphic computing presents significant opportunities for advanced buffer solutions. AI hardware architectures require massive parallel signal distribution with precise timing characteristics, creating demand for specialized buffer arrays. Memory interfaces in these systems increasingly operate above 8Gbps, where traditional buffers struggle to meet timing requirements. Suppliers developing low-latency, high-fanout buffer solutions are well-positioned to capitalize on the AI semiconductor market, which is growing at over 35% annually.

Automotive Sensor Fusion Drives Buffer Innovation

Advanced automotive sensor suites incorporating radar, LiDAR, and camera systems require robust signal conditioning solutions. These multi-modal sensing platforms generate vast amounts of analog data that must be conditioned before analog-to-digital conversion. Buffer manufacturers developing specialized solutions for sensor interfaces can capture significant value in this high-growth segment. The automotive sensor market is projected to exceed $50 billion by 2030, with buffer ICs representing a critical enabling technology for next-generation ADAS implementations.

3D IC Packaging Creates Buffer Integration Opportunities

The shift toward 3D IC architectures and heterogeneous integration creates new possibilities for embedded buffer solutions. Through-silicon vias (TSVs) and other vertical interconnect technologies require specialized buffering to maintain signal quality across stacked dies. Suppliers developing buffer IP for 2.5D/3D implementations can establish strong positions in advanced packaging supply chains. The 3D IC market is expected to grow at 20% CAGR, driven by performance demands in high-performance computing and mobile applications where space constraints are particularly severe.

LOGIC BUFFER MARKET TRENDS

Expansion of High-Speed Data Transmission to Drive Logic Buffer Demand

The rapid expansion of high-speed data transmission networks, including 5G infrastructure and cloud computing, is significantly accelerating the adoption of logic buffers. These components play a critical role in signal integrity management across complex integrated circuits, ensuring reliable data transfer even in high-noise environments. With data traffic projected to grow at a compound annual growth rate of over 25% between 2024 and 2032, semiconductor manufacturers are increasingly incorporating advanced buffer solutions into their designs. Furthermore, the transition towards higher bandwidth interfaces like PCIe 6.0 and DDR5 memory standards is pushing buffer technology to operate at speeds exceeding 8 GHz while maintaining signal fidelity.

Other Trends

Automotive Electronics Revolution

The automotive industry’s electrification and autonomous driving trends are creating substantial demand for robust logic buffer solutions. Modern vehicles now incorporate over 150 electronic control units requiring precise signal conditioning between sensors, processors and actuators. Logic buffers with enhanced ESD protection and wide temperature range operation (-40°C to +125°C) are becoming essential for advanced driver assistance systems (ADAS) and infotainment platforms. This segment is expected to account for nearly 30% of the total logic buffer market by 2030 as vehicle architectures transition toward centralized domain controllers and zonal architectures.

Miniaturization and Power Efficiency Innovations

The relentless push for smaller form factors and lower power consumption in consumer electronics is driving significant innovations in buffer IC design. Semiconductor companies increasingly focus on developing buffers with sub-1V operating voltages and package sizes below 1mm² to accommodate space-constrained applications like wearables and IoT edge devices. Advanced buffer architectures now incorporate dynamic power scaling features that can reduce idle power consumption by up to 75% compared to traditional implementations. These developments align with increasing regulations on electronic device energy efficiency while meeting the performance requirements of next-generation mobile processors.

Industrial Automation Adoption

The global industrial automation wave is creating new opportunities for specialized buffers in harsh industrial environments. Factory automation systems require buffers with enhanced noise immunity and ruggedized packaging to withstand vibration, dust and electromagnetic interference. New industrial-grade buffer solutions featuring galvanic isolation and reinforced outputs capable of driving long cables (up to 30 meters) are gaining traction as smart factories expand. This application sector is projected to grow steadily at approximately 15% annually through 2032, supported by Industry 4.0 initiatives worldwide.

COMPETITIVE LANDSCAPE

Key Industry Players

Semiconductor Giants Compete Through Innovation and Strategic Expansion

The global Logic Buffer market features a dynamic competitive landscape with established semiconductor leaders dominating revenue shares while smaller players carve out specialized niches. Texas Instruments emerged as the market leader in 2024, commanding approximately 22% of global revenue share through its extensive product portfolio and strong foothold in industrial and automotive applications. The company’s leadership stems from continuous investments in high-performance buffer ICs and strategic partnerships with Tier-1 automotive suppliers.

NXP Semiconductors and STMicroelectronics collectively held nearly 30% market share, benefiting from their vertically integrated manufacturing capabilities and focus on energy-efficient buffer solutions. These companies are aggressively expanding their production capacities in Asia to capitalize on the region’s growing electronics manufacturing sector.

The market also witnessed notable consolidation activities, with onsemi acquiring two smaller buffer IC specialists in 2023 to strengthen its position in the industrial automation segment. Meanwhile, Toshiba and Renesas are leveraging their legacy in power management ICs to develop advanced buffer solutions for 5G infrastructure and IoT devices.

Emerging players like SGMICRO and Highland Technology are gaining traction through innovative product designs, particularly in space-constrained consumer electronics applications. These companies focus on delivering high-speed tri-state buffers with lower power consumption compared to industry standards.

List of Key Logic Buffer Manufacturers

Texas Instruments (U.S.)

NXP Semiconductors (Netherlands)

STMicroelectronics (Switzerland)

Diodes Incorporated (U.S.)

Nexperia (Netherlands)

onsemi (U.S.)

Toshiba Electronic Devices & Storage Corporation (Japan)

SGMICRO (China)

Highland Technology (U.S.)

Maxim Integrated (U.S.)

Renesas Electronics (Japan)

Segment Analysis:

By Type

Single-ended Buffer Leads the Market Due to Wider Adoption in Consumer Electronics and Industrial Applications

The market is segmented based on type into:

Single-ended Buffer

Subtypes: Non-inverting, Inverting, and others

Tri-state Buffer

Differential Buffer

Others

By Application

Consumer Electronics Segment Dominates Due to Increasing Demand in Smart Devices

The market is segmented based on application into:

Industrial

Consumer Electronics

Automotive

Others

By Voltage Level

Low Voltage Buffers Hold Significant Market Share Due to Energy Efficiency Requirements

The market is segmented based on voltage level into:

Low Voltage (Below 3.3V)

Medium Voltage (3.3V-5V)

High Voltage (Above 5V)

By Package Type

Surface Mount Packages Dominate Due to Miniaturization Trends in Electronics

The market is segmented based on package type into:

Surface Mount

Through Hole

Others

Regional Analysis: Logic Buffer Market

North America North America, particularly the U.S., dominates the logic buffer market due to high demand from the consumer electronics and automotive industries. The presence of key semiconductor players like Texas Instruments and Maxim Integrated, combined with strong R&D investments in advanced electronic components, drives innovation and adoption. The U.S. accounted for approximately 35% of the global market revenue in 2024, supported by robust manufacturing infrastructure and increasing smart device penetration. Canada and Mexico are also witnessing steady growth, fueled by cross-border supply chain integrations and rising automation needs in industrial applications.